Recent News and Updates

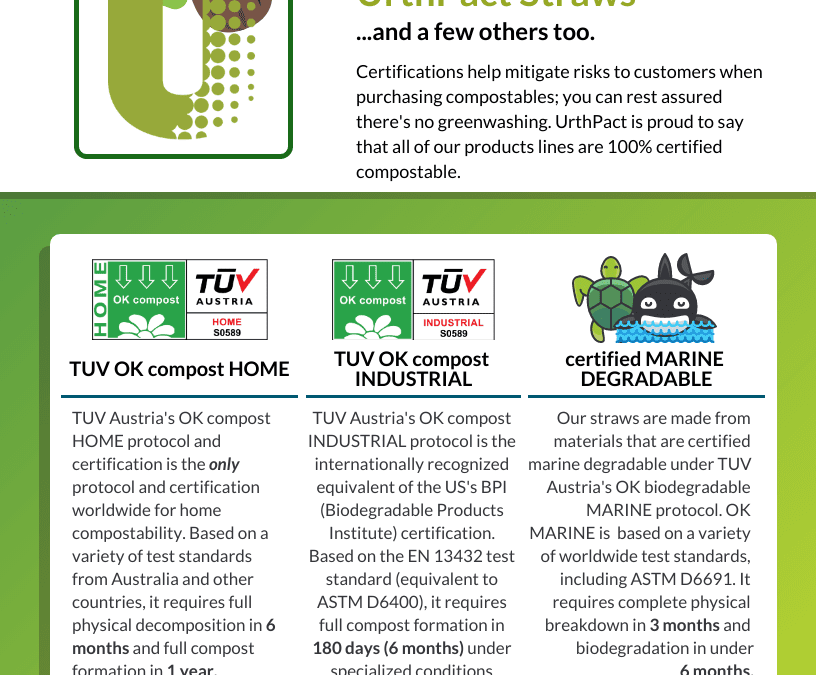

3 Biggest Straw Certs

How Ironic! UrthPact – A Company Located in The Pioneer Plastic City – Is Molding the Future of Sustainable Plastics

Drive about an hour west of Boston and you’ll find a small city called Leominster. With a population of just over 41,000 and a history deeply rooted in the manufacturing industry, Leominster holds an ominous and historic nickname: The Pioneer Plastics City. Now hang on; we know that being known as the Birthplace of Modern Plastics may not exactly be the best of nicknames in today’s day and age. But as a member of a community and a city that has always been a leader in the plastics industry, UrthPact has engineered and contributed the solution to the plastic pollution problem. In doing so, UrthPact hopes that their home town will be soon known as the Pioneer Bio-Plastics City.

Quick history lesson first: originally a part of nearby Lancaster, Leominster itself was incorporated in 1740, and was a major stop on the Underground Railroad during the Civil War. What started out as mainly a farming community quickly moved to manufacturing around the turn of the 19th century, with the opening of the Fifth Massachusetts Turnpike and the addition of the Fitchburg and Worcester railroads that ran straight through the center of town. One of the largest manufacturing industries that succeeded in Leominster was the comb industry (keep in mind, we’re still pre-plastic here, so comb-making was a painstaking and time-consuming process). Comb-making was then revolutionized in 1868 by the invention of “celluloid,” one of the first plastic materials. Production skyrocketed, and Leominster was dubbed the “Comb City.” The next turning point came in the early 1930s when Samuel Foster brought the process of injection molding to Leominster, which further expanded a plastic manufacturers’ capabilities. The introduction of injection molding would earn Leominster the moniker of the “Pioneer Plastics City.”

Leominster would continue to be a leader in the plastics industry throughout the 20th century, with many iconic products originating there, including Tupperware and the pink lawn flamingo. The late 20th century marked the first large-scale decline in plastics manufacturing in Leominster, as operations were made cheaper by moving them overseas. But it was also around this time that UrthPact CEO Paul Boudreau had begun his journey in the plastics industry, one that would lead to him and UrthPact becoming a world leader in compostable bioplastic manufacturing.

Bourdeau began his work in plastics with the goal of manufacturing items that anyone else said was impossible to do in the world of injection molding. And he succeeded. He built a very successful injection molding business that contracted to a variety of organizations, creating a wide range of previously impossible-to-make products. However, a walk on the beach one spring on a family trip to the coast of Maine put things into perspective. Boudreau noticed a variety of plastic remnants littered on the shore, and he could connect himself to nearly every single piece he found. He realized then that in an effort to make a mark on an industry, he had left a terrible scar on the planet. As an established member of the Pioneer Plastics City and the injection molding industry, he decided it was time to change the face of plastics to find a more sustainable solution.

And in 2013 Boudreau founded UrthPact – a company focused on the manufacturing of single-use compostable bioplastic products. The company motto is to create a world where consumption leaves no footprint, and they’ve set a goal of keeping 25 billion plastic pieces from reaching oceans and landfills by 2025. With innovative techniques and a wealth of engineering knowledge, Boudreau and his team have built one of the largest and most successful bioplastic manufacturing companies in the world. Still located in Leominster, they’ve added another goal to the list: to change the reputation of the Pioneer Plastics City, to break the status quo in Leominster that was set almost 150 years ago with the introduction of celluloid. Boudreau and UrthPact were recently featured in WCBV-TV’s Chronicle special “Know Your Nicknames,” where Boudreau talked about the importance of bioplastics, and how UrthPact is working to introduce them to the world as the solution to the single-use plastics problem. Some of the other towns included in the program were Carriage Town (Amesbury), Chair City (Gardner), the Kielbasa Capital of the World (Chicopee), the Asparagus Capital of the World (Hadley), Watch City (Waltham), and Leather, or Tanner City (Peabody). But there’s no shortage of nicknames in Massachusetts; honorable mentions from the episode include Tool Town (Athol), Jump Town (Orange), Toy Town (Winchendon), Witch City (Salem), Whaling City (New Bedford), the Birthplace of American Liberty (Lexington), Sliver City (Taunton), and Shoe City/”the City of Champions” (Brockton).

Leominster and the plastics industry is changing. Both manufacturers and consumers recognize that we need a more sustainable solution than traditional, petroleum-based single-use plastic products. The problem started close to home for us here at UrthPact, and now we’re solving it. Leominster is still very much a pioneer city in the plastics industry – just a much more sustainable one. How often do you see a solution arise from the same community that was one of the original leaders for the problem? Innovation and leadership have always been our specialty at UrthPact, and we don’t plan on stopping anytime soon. Before you know it, the sign you drive past to enter our city will read: Welcome to Leominster, The Pioneer Bioplastics City.

Innovative Materials Solve Plastic Pollution

When you ask the average person, “What’s the easiest and quickest way to solve plastic pollution,” odds are, they’ll tell you to stop using single-use plastics. Skip the straw, use paper grocery bags, a reusable water bottle, the whole nine yards. But how are we supposed to send food to the far reaches of the world, drop clean water in war-torn areas, or protect ourselves from deadly pandemics like COVID-19? The truth is, single-use products are a necessity. What isn’t a necessity is plastic. When we began producing these single-use products, plastic was a quick, functional, and most importantly–cheap–option. However, we never considered the long-term consequences that would fall on our planet. Back then, plastic really was the best option for single-use products. But today, we have materials that can function just as well as plastic, and cause little or no harm to our planet. The key to solving plastic pollution isn’t elimination, it’s innovation.

What type of innovative material could replace plastics in the manufacturing of single-use products? Simple: bioplastics. Bioplastics are materials that function similarly to petroleum-based plastics, but are made from a biological base, and are biodegradable at the end of their life. This makes both their beginning-of-life (production) and their end-of-life (disposal) much more environmentally friendly, while still providing the functionality that is needed from a plastic material. Bioplastic materials can be molded, extruded, and blown into a variety of products that could easily replace their traditional plastic counterparts. With a much more sustainable beginning of life, these materials are already better than those that are petroleum-based.

When it comes to the material’s end of life, most bioplastics are compostable, meaning they will break down into usable compost in a relatively short amount of time (under one year). There are two categories of compostable bioplastics: industrial and home. Industrially compostable materials need to be taken to a specialized facility that can control other variables during the composting process, like moisture, temperature, and airflow. Home compostable materials can biodegrade anywhere on Earth–even in the oceans with the proper material thickness. Traditional plastics on the other hand simply break down into smaller and smaller pieces, leaching toxic chemicals into the environment as they do so. The end-of-life for compostables has no negative effect on the planet and actually provides a positive product to be used to support the growth of new feedstocks for the next generation of bioplastic materials.

Single-use products have made it possible for us to keep the world healthy, fed, hydrated, and safe. The solution for solving the planet’s plastic problem shouldn’t require us to give up the convenience and necessity of single-use products. And realistically, it doesn’t have to. Compostable bioplastic materials make it possible to have all the functionality required and expected of single-use plastics, but with none of the environmental impact that comes from utilizing petroleum-based materials. Single-usage isn’t the problem, the material is. And we’ve found the solution. The plastic pollution problem has truly been solved.

2021: The Year of Sustainability

2021 here we come! We’re all excited to put this rollercoaster of a year that was 2020 behind us, and move on to the *hopefully* promising future to be held in 2021. With vaccines in distribution for COVID, 2021 is already looking better than 2020. On top of planning for getting COVID under control, there are some other problems to be considered and handled in 2021. One of the biggest being plastic pollution and sustainable business practices. Many sustainability goals and plastic pollution movements were put on hold this year to deal with the coronavirus, and plastic usage and pollution spiked dramatically. Masks, gloves, and other single-use products that were necessary to fight this pandemic are now strewn about our natural world as litter and pollution. We know that single-use products are an important part of our society, and we’re here to change the narrative: single-usage isn’t the problem, the material is.

Sustainability goals are a key part of modern business. Consumers look to purchase from organizations that are doing their part to protect and give back to our planet. As we look forward into 2021, we want to provide a resource to help businesses set sustainability goals that will not only appeal to customers, but will also help to solve the truly pressing environmental issues that our planet is facing. At UrthPact, we see plastic pollution as one of the biggest issues threatening our planet, especially with the spike in usage brought on by COVID. It’s all of our responsibility to do our parts to solve the plastic pollution problem, and we’re here to provide some great goals for the new year to help you reduce your plastic usage and waste.

One of the most common and simplest sustainability goals is to eliminate as much single-use plastic and packaging from your business as possible in a certain timeframe. We recognize that achieving these goals won’t happen overnight. However, there are lots of plastic products that we throw away that can easily be replaced by a reusable alternative. For example, instead of having a vending machine with plastic water bottles, provide your employees with reusable bottles and then have a bottle refill station instead. You’ll save money in the long run on disposable bottles and recycling efforts, as well as keep a lot of plastic out of the environment. In the restaurant industry, reusables are great for take-out containers, and they can create a loyal customer base as well.

Now what about the single-use products that it doesn’t make sense to make reusable, like straws? We realize that there are certain products that make sense as disposable and single-use. However, we started making those types of products out of a material (plastic) designed to last for hundreds of years, just because it was easy and cheap. Whenever you do have to utilize a disposable product, try to find a compostable option to provide to your customers. Many home compostable bioplastics can be disposed of with general waste to landfills, where they will break down anaerobically, or can head straight to a composter alongside normal food waste compostables. These materials will continue to become more commercialized in coming years, as bans on single-use plastic product lines become more common worldwide.

Providing compostable alternatives not only helps the end-of-life solution for single-use products, but it contributes to benefits at the beginning of life as well. Compostable bioplastics are made from plant and natural canola bases, and the material production process is much more planet healthy than that of traditional, petroleum-based plastics. So you not only help to conserve resources, but actually remove harmful greenhouse gases from the atmosphere when you purchase and utilize compostable bioplastic disposables.

Another great alternative to traditional petroleum-based plastic disposables is utilizing a recycled-content alternative whenever possible. Now, this can be pre-consumer recycled-content (ie, excess material from the manufacturing process that is reground, mixed with virgin material and used again), or post-consumer recycled-content (ie, the product was utilized by a customer, recycled, and used to make a new product). While recycled-content options may not be as great of an option for single-use products (they’ll end up sitting in landfill eventually because most materials can only take 1-2 trips around the recycling cycle before they’re of too low quality to be recycled again), they do have a better environmental footprint than virgin plastic products.

Another great sustainability goal is to conserve or optimize resource use within your business. This could have to do with raw materials used to produce product or electricity, water, and other resources needed to run a business. By reducing or making more efficient use of resources, you can not only save money, but help to protect the environment as well. If you do need to utilize electricity and other resources, try to get them from sustainable sources, or purchase sustainable energy credits to offset your energy usage. This helps move your business closer to being carbon-neutral, as well as allows you to better allocate the resources you do use across a wider range of your business.

Finally, we have the realistic piece of sustainability goals: making sure they actually can be achieved and work in practice. If you implement industrially compostable products into your single-use product lines but there is no composter in your area or no collection system in place, then you’re not really making a whole lot of difference. However, if you help your community to implement a compost collection system for its residents, then you have completed the circular lifecycle for the compostable products. For recyclables, make sure that there is an available recycling system for that particular type of plastic in your area before implementing a recyclable product. It’s key for businesses to complete the loop and provide customers with proper end-of-life solutions for your products so they can be recycled or composted in practice and not just in theory.

There are an infinite number of sustainability goals you can set for 2021. Zero waste goals, energy conservation goals, packaging sustainability goals–the possibilities are truly endless. In this time of COVID, plastic pollution has become a widespread issue. And it’s a key issue to address in the new year. At UrthPact, our goal is to help our customers to achieve their sustainability goals by implementing our compostable single-use product lines, as well as educating our network on compostable bioplastics, certifications, and other subjects relating to the plastic pollution solution. Straws, single-use cutlery, and coffee packaging products are our three main areas of focus, and our goal is to keep 25 billion pieces of plastic from reaching oceans and landfills. The future is a sustainable one, and we’re here to help bring it to fruition.

If you’re looking to get in touch with us about getting UrthPact compostables into your business, head over to one of our handy contact forms from our website (straws, cutlery, or coffee packaging), or our general contact us form.

Green Marketing Tips for Compostable Products

2021 is going to be a year of sustainability. Besides being, well–a new year–there was a huge spike in plastic pollution in 2020 due to the coronavirus pandemic. And that brought plastic pollution back to the forefront of everyone’s minds. Businesses are looking for opportunities to make changes, and to eliminate as much plastic from their operations as possible. Compostables are a great alternative in the space of single-use plastics, however it can be quite confusing to navigate the world of green marketing. While there are some federal restrictions and guidelines when it comes to preventing greenwashing, many states also have individual regulations, and specific cities can have even more restrictions as well. We’re here to assist you in understanding the green marketing process, and also to help eliminate discouragement about utilizing and providing compostable products just because their marketing is a bit more complicated.

Our first tip: avoid vague phrases like “eco-friendly,” “greener than before,” and other similar phrases. These types of phrases can be misleading because they don’t convey to the consumer the exact environmental benefit that the product provides. In the case of green marketing, the more specific you can be in your claims, the better. This will encourage consumers to trust your brand because you are up front about your product, and it protects you from legal action that may be taken against you. Tip number 2 is to always be able to back up claims with scientific evidence. Whenever you make an environmental claim of any sort, have the test reports to back up that claim. While you don’t have to list out results on the packaging, it’s important to have them on-hand should a consumer or customer request them. Tip number 3 completes the trifecta: always have compostable products certified by the proper certifying body, and convey those certifications prominently on packaging. By completing and displaying your certifications from organizations like BPI and TUV, you are confirming that you have backup from multiple sources for your claims.

Besides this trifecta of steps you can take to backup your claims and protect your business, and mitigate risk for your customers, there are some general phrases you can use that can be helpful to your customer. For a home compostable product, you have the most freedom. Phrases like, “backyard compostable” and “biodegradable in any terrestrial environment” can safely be applied to home compostable products. As always, we recommend obtaining a TUV OK compost HOME certification to be sure you have the proper backing to your claims. For industrially compostable products, it’s important to be clear about the difference between home and industrially compostable. Phrases such as “compostable in municipal facilities” or “compostable under specialized and controlled conditions” make it clear to the consumer the importance of proper disposal for industrial compostable products. Most industrially compostable products also include disclaimers encouraging consumers to ensure that there is an industrial composting facility in their area as well. As always, get the product certified by either TUV’s OK compost INDUSTRIAL or BPI in order to ensure you have backed your claims.

The last note we want to make is on marine biodegradable claims. Newly developed bioplastic materials can be certified for biodegradation in a marine environment by TUV’s OK biodegradable MARINE. However, to avoid having consumers toss trash in the ocean, this certification cannot be conveyed on products that are not meant for use in a marine environment (for example, drinking straws). To work within the rules, you can state that these types of products are “made from a certified marine degradable material” or that they “will biodegrade in oceans, should they accidentally end up there.”

Green marketing is a complex and tricky world. You want to properly convey the environmental benefits of your product to your customers without being misleading and while protecting your intellectual property. There is a fine line you have to walk. But, by making specific and clear claims that are backed by scientific reports and third-party certifications, you can protect your business, your customer, and most importantly, the planet.

How UrthPact Can Help YOU Achieve Your Sustainability Goals

Sustainability. Something that’s been on the minds of many companies, businesses, and organizations, especially in recent years. Many have even set 5- and 10-year goals to reduce energy consumption or to make their packaging completely environmentally-friendly. And while setting goals is the first step towards a healthier planet and sustainable business, it’s achieving those goals that some companies struggle with. You can find environmental problems in nearly every nook and cranny of the business model, especially in industries like restaurants, manufacturing, and energy. If you’re struggling with goals you’ve set, or you don’t know what type of goals you should be setting but want to be more environmentally friendly, then UrthPact is here to help.

Sustainability goals vary by industry. Many are focused on energy usage, greenhouse gas emissions, or packaging solutions. Setting your sustainability goals is a team-wide effort. And, even a small goal can make a big difference over a long period of time. If you exceed your goal early, you can always reset it even higher! You can break down corporate sustainability initiatives into six areas: pollution prevention, resource conservation, zero waste to landfill, waste reduction/minimization, zero discharge, and reduce carbon footprint/zero emissions.

Let’s start with pollution prevention categorized goals. Pollution can occur in a variety of different environmental areas, including air, water, soil, and others as well. These types of sustainability goals aim to eliminate waste at the source. Things like reducing carbon emissions and waste reduction fall under this broader umbrella of pollution prevention. These goals can be achieved in a few different ways. Choosing less toxic materials in the manufacturing sector, or modifying production processes to emit less waste and emissions are great ways to reduce greenhouse gases or physical polluting waste. Along similar lines, conservation techniques can be implemented in parallel with eliminating waste. The classic reduce, reuse, and recycle method also applies here for physical components like packaging and supplies as well.

Next, we have resource conservation goals. Many organizations look to reduce water, electricity or energy, and raw materials. Simple things like optimizing water efficiency and utilizing automatic shut-off lights and energy-efficient bulbs can be easy changes that make a big difference. Innovation in production can also help to reduce scrap material as well, or to reuse it in new products. A great example of resource conservation comes from Bosch, who has a 6-pronged set of sustainability goals that cover a wide variety of fields, including energy, climate, health, globalization, water, and urbanization.

Zero waste to landfill. This goal is a lofty one and looks to eliminate ALL of an organization’s waste that would normally be taken to landfill. This is a specific component of a zero-waste goal, not the equivalent overall of zero waste. Zero waste to landfill indicates that absolutely no manufacturing waste is headed for landfills. Some companies try to cheat this type of goal by incinerating their waste, but this usually creates ash that then must be landfilled. A variety of cities in the US have zero waste goals, including New York, Minneapolis, Washington DC, Washington state, San Francisco, San Diego, Dallas, and Austin. Even large food and beverage organizations like Nestle have committed to reaching 100% zero waste by 2030.

The next area of sustainability goals is waste minimization and waste reduction. These are the stepping stones towards implementing a zero waste to landfill goal. Essentially, if zero waste is too lofty a goal, or would take a very long time to achieve that it’s not a realistic goal to set, this is the next best thing. And, after achieving waste reduction and minimization, goals for zero waste can be set for the future. Some methods include source material reduction, or utilizing environmentally-sound recycling methods for materials, energy, and other resources. Amcor has committed to making 100% of their packaging either recyclable or reusable by 2025, and to utilizing more recycled materials as well.

Moving forward, we have zero discharge sustainability goals. This means to eliminate discharge pollutants from a point source (like a manufacturing or processing plant), especially into local waterways. Some organizations go for total discharge elimination, while some focus on specific (and usually more toxic) pollutants. These goals also require organizations to be good water stewards, in which the company is aware of and understands their water usage and water governance in their areas. One of the most common methodologies is to recycle industrial wastewater by treating it and transferring pollutants to a solid waste sludge. Levi Strauss & Co works to preserve fresh water for drinking and other uses through water recycling.

Finally, we have zero emissions goals. This is your classic reduction of the carbon dioxide emissions goal. Using energy-efficient machinery, as well as EPA tracking systems that will help measure and regulate carbon emissions are some of the simplest methodologies to reducing carbon dioxide emissions. Investing in renewable energy and utilizing electric or fuel-efficient fleet vehicles are also great ways to reduce emissions. Some great real-world examples are GM working towards a zero-emissions future and Ball Corp looking to cut the carbon footprint of their beverage cans by 25%.

So how can UrthPact play into all of these sustainability goals? We believe in creating a world where consumption leaves no footprint, and therefore everything we do is to create a more sustainable world. Our main focus is on the plastic pollution problem. Single-use plastics are one of the biggest pollutants in today’s world, and our goal is to eliminate 25 billion plastic pieces from oceans and landfills by 2028. We focus on three main product lines to help companies reduce their amount of plastic usage: coffee packaging (pods and valves), single-use cutlery, and single-use straws.

All of our products are made from compostable bioplastic or recycled-content materials. Our coffee packaging and cutlery are currently made from an industrially compostable bioplastic called PLA. Products made from PLA have a completely circular lifecycle, meaning they allow you to have pollution prevention, lowered emissions, and conserve natural resources. Industrially compostable products fit into sustainability goals surrounding packaging. These types of goals usually require that all packaging be reusable, compostable, or recyclable (in practice). While compostables are difficult to implement in a variety of applications, single-use products are the perfect niche for this type of product. As long as you manage waste and ensure there is a practicing composter in your area, this type of product is the perfect solution.

Our straws are the special exception. While our cutlery and coffee packaging are industrially compostable our straws are home compostable, meaning that they can break down anywhere on Earth in under a year. By partnering with us on straws (we do white-label and private-label solutions), you can eliminate a huge piece of the single-use problem within your business. It allows you to reduce waste, and the straws can be easily disposed of with compostable food waste. And should they end up in landfills, they will still biodegrade completely to innocuous elements in under a year. So while there is still waste to landfill, that waste will not sit in the landfill for hundreds of years like its plastic counterparts would. And that’s the difference. On top of all that, our straws are also marine-degradable, meaning they’ll completely biodegrade in the ocean, should they accidentally get there. This makes our straws the best of every world. Plus, we guarantee customer satisfaction. All the functionality you’d expect from plastic with none of the environmental guilt.

Compostables are a niche product. But they cover more areas of sustainability than you may think. For example, because compostable bioplastics are made from cornstarch, sugar cane, or canola, they actually pull carbon dioxide from the atmosphere. On the other hand, traditional plastics release carbon dioxide that was sequestered away for millions of years. Overall, compostables pull carbon while petro-based adds carbon. Differences like these allow compostables to cover a variety of sustainability initiatives within your business.

So, to sum it all up: UrthPact compostables provide a great opportunity to help achieve your sustainability goals, especially when those goals are centered around waste and packaging. We encourage any organization to set some kind of sustainability goal, even if it’s a small one. If everyone just takes one small step forward in the field of sustainability, we can end up taking a giant leap as a society. The planet is depending on us to protect it; it’s time we stepped up.

How a Compostable Lifecycle Benefits the Planet

We all know that plastic pollution is a huge problem facing not only our planet but our society as well. While recycling does have the ability to create a better lifecycle for petroleum-based plastic products, it isn’t the most efficient system we have. When you look at the lifecycle of a product, you not only have to consider the life of the product, but the life of the material as well. Petroleum-based plastics are made from oil that formed from organic matter over the course of 50 million years. Essentially, really REALLY old carbon. Carbon that was safely sequestered away that we are now going to pump into not only our atmosphere, but our oceans, our roadsides, and our landfills. We’re looking for a method and material that removes excess carbon, not adds it. There has to be a better solution, one that utilizes newer sources of carbon and cleaner production methods.

Well, surprise surprise, there is. Compostable bioplastics are made from plant-bases, which therefore makes their starting point a new carbon source, rather than an old one. And, rather than taking 50 million years to form, like oil, the two main necessary crops–sugar cane for industrially compostable PLA and canola for home compostable PHA–are fully mature in 14 and 4 months respectively. Therefore, the beginning of life for these materials is infinitely better when compared to that of traditional plastics: it’s more sustainable, it’s better for the environment, and it takes less time. A similar statement can be made for the end of lives of these materials. Both PLA and PHA will return to usable compost in under a year’s time (in the proper facilities and conditions in the case of PLA). However, no matter where plastics end up–even if they’re recycled–they will end up in landfills where they will sit for somewhere between 500 and 1000 years. And if they end up anywhere else, they often break down into microplastics, which are highly toxic and dangerous to the environment and to wildlife.

When it comes to the middle part of the lifecycle (ie, actually producing, selling, utilizing, and disposing of a product from one of the 3 materials), it’s pretty similar across materials in the case of time. However, they differ in sustainability. Molding and producing products from petroleum-based materials is, in general, a more harmful process to the planet than the same process done with compostable bioplastic materials. Whenever you work with petroleum-based materials, some amount of carbon dioxide and other greenhouse gases are released into the atmosphere, which makes it a more environmentally detrimental process.

At UrthPact, our goal is always to work towards creating a world where consumption leaves no footprint. Our compostable products lines help to push the plastics economy in the US to be more circular by implementing compostable solutions where applicable. Single-use foodservice products are a great niche for compostable products and packaging that can be disposed of in compost with food scraps. Currently, our straws are home compostable and biodegrade anywhere on Earth, while our cutlery and coffee products are industrially compostable. Each step forward is a step towards keeping 25 billion pieces of plastic out of oceans and landfills. Each step creates a world where consumption leaves no footprint.

25 Billion Pieces of Plastic – The UrthPact Story

When UrthPact was founded, we set a goal — to create a world where consumption leaves no footprint. We wanted to provide society with a solution to plastic pollution, with all the functionality needed, but without the environmental guilt and negative impacts of petroleum-based plastics. And while we set out with our abstract goal in mind, we wanted to also make our results qualitative and trackable; how many pieces of plastic could we prevent from reaching landfills and oceans by replacing them with a compostable solution? That goal was set at 1 billion. Wouldn’t it be cool if we could do something like a billion pieces, we thought. Little did we know that 1 billion pieces would simply become a blip on our radar.

Eventually, that goal was increased to 2.5 billion pieces. UrthPact was growing, and we were finding new and innovative solutions to a variety of plastic pollution problems (coffee pods, cutlery, etc.). But 2.5 billion wasn’t good enough for CEO Paul Boudreau. “I had probably put more than 2.5 billion pieces of plastic on this planet during my time working in petroleum-based plastics,” he said. “I want to completely make-up for what I created in the past.”

Then came the challenge. Paul’s business coach brought up the idea of multiplying all of his goals by 10. The idea was to drive business and development forward by setting lofty goals, rather than smaller goals that could easily be achieved. This drove the goal up to 25 billion pieces of plastic kept from oceans and landfills by 2028. That’s when our eyes were truly opened to the possibilities of what we could create, what type of legacy we could leave. As pioneers in the compostable bioplastics field, UrthPact was uniquely positioned to leave a mark on society and the planet.

It’s been 2 years since we upped the goal to 25 billion. As of August 2020, we had already reached the 8 billion pieces mark (check out our homepage for the current count). And we can only go up from here. As we expand current product lines and find new solutions, the number will only rise faster than it already is. We truly have found the solution to the single-use plastics problem. Soon enough, even the 25 billion mark will just be another milestone. We will create a world where consumption truly leaves no footprint.

Bringing Back Single-Use Plastics Bans

Bags. Straws. Bottles. What do they all have in common? You guessed it, they’re all single-use plastics. They’re also all currently being targeted by a variety of plastics bans worldwide. Plastics bans are any form of legislation that restricts the production, use, or distribution of single-use plastic products. They can be implemented at all levels of government, and have created a strong driving force for society to make changes in their views and dependence on single-use plastics. Plastics legislation has taken a backseat in the beginning half of 2020, but it’s more important now than ever for us to take a hard look at what we can do to curb the plastic pollution problem.

Of the 50 states in America, 26 of those have some kind of restriction on single-use plastics. These regulations and restrictions vary widely, geographically and in content-matter. Some states like California have a ban on plastic bags across the state, but straw bans only in certain cities. Montana bans plastic straws and in their national parks, including Yellowstone and Glacier National Park. Washington DC has completely banned plastic bags and straws within the city limits. These differing restrictions are due to the fact that the US has no federal regulations on single-use plastics.

127 countries worldwide have restrictions on plastic bag usage, production, and distribution, and 27 countries have restrictions on particular single-use plastic products or materials, outside of plastic materials. It’s key to understand how these regulations work in the hierarchy of government to truly understand their impact. Essentially, the highest level restrictions and legislation are at the federal level. All states and local governments must comply with standards set by the federal government. At the state level, states can further restrict plastics usage from that set at the federal level, but not loosen restrictions. So, if the federal government has banned all plastic bags, a state can decide to also ban plastic straws, but cannot decide they want to allow plastic bags. It’s a similar situation at the local level. Individual municipalities can further restrict state legislation but cannot loosen it. This is why you often see straws banned only in particular cities within a state.

Because federal legislation is the “all-powerful umbrella” when it comes to plastics bans, it’s key for federal governments to take steps to at least reduce the usage and production of single-use plastic products. Simple concepts like making manufacturers and distributors responsible for the end-of-life of the plastics they utilize have the potential to make a huge difference. The coronavirus pandemic put many plastics bans on hold, or even caused those in place to be removed. Now, single-use plastic pollution has spiked to unheard of levels, and we need to make changes to curb the issue. Bans on single-use plastics are a great start, as well as a great motivator to encourage people to make more sustainable choices. While bans can’t solve the plastic pollution problem on their own, they can open doors for innovative solutions that will help us to save the planet.

World CleanUp Day 2020 – How UrthPact’s Compostable Products Clean the Planet

25 billion pieces of plastic. A world where consumption leaves no footprint. Both of these missions are what drive everyone at UrthPact every single day. Every compostable piece we manufacture, every sale we make, brings us closer to these goals. With World CleanUp Day tomorrow, we want to encourage everyone out there to do something for the planet. Pick up trash while on your daily walk, participate in a beach cleanup, or even something as simple as declining a plastic straw with your morning iced coffee and opting for a more sustainable option like reusable or home compostable. Every single person making one small change has the ability to create ripples through a society, and reach further than you could imagine.

When UrthPact was founded, we set a goal of creating a world where consumption leaves no footprint. We recognize that society requires the convenience and use of plastic products, but we want to be able to provide that convenience without putting a burden on the planet. That’s why all of our product lines are compostable–either commercially or home compostable. Each product we sell helps to eliminate the need for their plastic counterparts, therefore reducing the need for plastic products throughout an industry. By providing a cost-effective and planet-healthy alternative, we continue moving towards a world where consumption leaves no footprint.

Not only do we have a goal of consumption without leaving a footprint, but we also set a goal to prevent 25 billion plastic pieces from reaching oceans and landfills. Every article we sell contributes to this goal. As of this week, we had crossed the 8 billion mark on our way to this goal. That’s enough pieces to circle the Earth almost 40 times. And we still have a long way to go. In order to reach the 25 billion mark, we still have to circle the Earth over 80 more times. That’s where all of our partners and customers come in. We truly would never have come this far, or have the ability to reach these goals without them.

So, as you head outside this weekend, take a minute to think about the planet. What can you do on a daily basis to help clean up your neighborhood? Could you switch from disposable plastic bottles to a reusable one? Could you choose paper bags at the grocery store rather than plastic? Maybe order compostable coffee pods instead of buying plastic ones? By making one small change in your daily routine, you just might influence the people around you to make changes too. Participating in World CleanUp Day 2020 is a great place to start your sustainability journey, and a great way to end the Summer of Sustainability. So pick up trash, choose sustainable single-use products, and encourage others to make the healthiest choices for our planet.