Recent News and Updates

UrthPact Introduces American-Made Compostable Straws for Sustainable Sipping

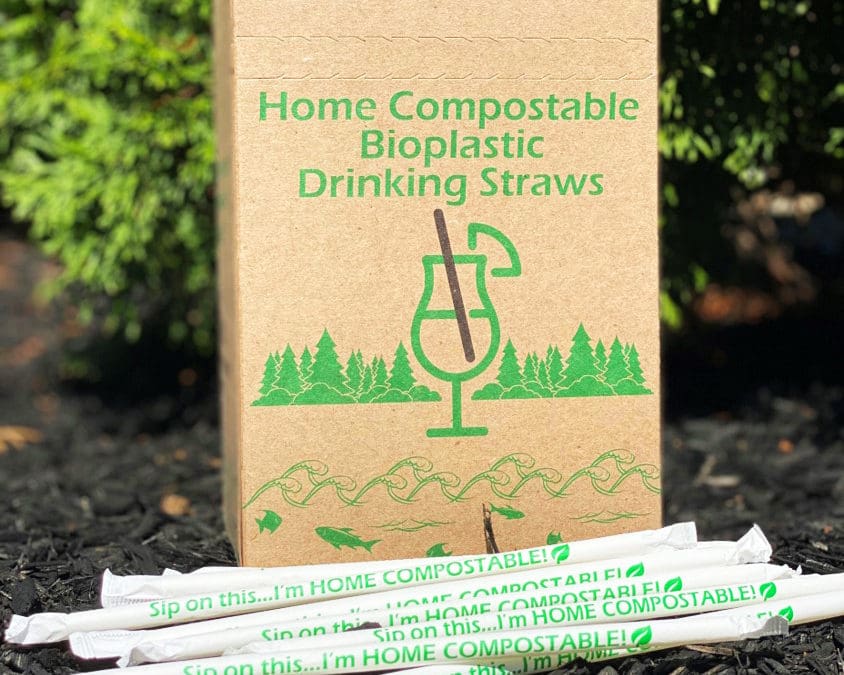

Boston-based American contract manufacturer UrthPact solves the single-use plastic straw problem with their new line of “never soggy,” single-use, home compostable drinking straws that perform “just like plastic.” Along with being home compostable, the straws are also marine-safe. Shipping now, the straws are available for private label brands and distributors to provide superior customer satisfaction to the quick service, restaurant, and other single-use industries.

Sep 8 2020 – LEOMINSTER, MA: UrthPact–a world leader in compostable bioplastic manufacturing–is now shipping their new line of home compostable drinking straws. The straws are engineered in partnership with Danimer Scientific, another world leader and developer of compostable bioplastic materials. With capacity in the billions for their first year, UrthPact will reduce the environmental impact of the single-use plastics industry, and put a dent in the 142 billion plastic straws used yearly in the United States alone.

The innovative straws are made with Danimer’s Scientific’s signature biopolymer NodaxTM PHA, which has been certified home compostable by TUV Austria’s OK compost HOME protocol. The material is a revolutionary step in the fight against plastic pollution from single-use products, as it is certified to compost in any environment on Earth in under a year, including landfill and marine conditions. UrthPact is the only contract manufacturer worldwide currently working to partner with nationwide and international brands, distributors, and other private-label organizations. The goal is to help expand their partners’ single-use product offerings and increase sustainability by carrying the home compostable straws under their own brands.

By addressing customer satisfaction and environmental benefits, UrthPact’s straws top all current single-use alternatives. They provide a superior drinking experience to paper straws, and are more environmentally friendly than other bioplastics like PLA (polylactic acids). They perform exactly as you’d expect a single-use plastic straw to–but without any of the environmental consequences.

As a USA-based manufacturer, UrthPact takes pride in providing products that are 100% Made in the USA. “Knowing exactly where and how your products are being made matters now more than ever,” says UrthPact CEO, Paul Boudreau. “Consumers are looking for an American-made product, and we’re here to help you provide that to your customers.” UrthPact’s facilities are also Safe Quality Food (SQF) certified, placing food safety and customer satisfaction at the top of their priority list, guaranteeing a contaminant-free and high-quality product.

“Home compostable straws are only the beginning,” Boudreau says. “PHA is a revolutionary new material in the world of bioplastics and has the ability to truly change the landscape of the single-use industry over the next 10 years. Single-usage was never the problem. The problem was we chose to use a material that was designed to last forever to make products only meant to be used for 5 minutes. With Mother Nature’s materials and our engineering expertise, we’ve truly solved the single-use plastic problem.”

Since its foundation in 2013, UrthPact’s goal has been to create a world Where Consumption Leaves No Footprint™. Taking their knowledge of the plastics industry, along with the mindset to save the planet, Boudreau and his team of engineers have created a wide range of compostable product lines, including coffee packaging, cutlery, and now straws. Straws will be the first home compostable product added to the portfolio, to be followed shortly by home compostable cutlery. They’re continuing to work towards preventing 25 billion plastic parts from reaching oceans and landfills. That’s enough parts to circle the globe 122 times.

UrthPact welcomes private-label brands and distributors to become partners. To learn more, click here. Restaurants, schools, and large institutions should contact their distributors to learn how they can order UrthPact’s new home compostable straws.

How Different Methods of Compost Benefit a Sustainable Future

There’s more to compost than meets the eye. Many people think of compost as just dumping your veggie peels, yard waste and/or fruit rinds into a bin in your backyard, and then over time having it turn into a useful fertilizer for your garden. But did you know that you can compost a wide variety of materials outside of just food waste, and on a much larger scale? Commercial compost facilities allow us to compost a wide range of food wastes, as well as other materials like yard clippings, grease waste, and compostable bioplastic waste. Combining this with increasing awareness and education for composting at home provides an incredible opportunity for society to reduce the amount of waste in landfills, as well as create a much healthier waste product.

The basic differences between industrial compost and home compost are the volumes at which they can be performed, the conditions under which they occur, and the location where they occur. As per their names, home composting can be done in your own backyard (or anywhere in nature for that matter), while industrial composting occurs in specialized facilities where temperature and other factors can be controlled and adjusted. Home compost is meant for smaller volumes of waste (from a single household for instance), while industrial compost is for entire communities or municipalities, similar to your local landfill or dump. Industrial composting helps to divert food waste and other compostables from landfills, not only reducing the volume of waste in landfills, but helping to lower greenhouse gas emissions as well.

There are three popular methods of industrial composting: aerated windrow, aerated static, and covered in-vessel. Aerated windrows are long, tall piles of compost that are manually turned in order to allow all of the materials to spend time in the center of the pile where temperatures are highest and composting occurs quicker. Aerated static piles are similar to windrows in their set-up, however they are aerated passively by adding layers of wood chips or shredded newspaper, or an airflow pipe system. Finally, covered in-vessel composting requires the most equipment. The waste is placed into a large drum, trench, or other vessel where temperature, air flow and moisture can all be controlled. This provides a much faster compost process, however the pile must sit for a time period after the process is complete so the microbial community can balance and the pile can cool. Each method has pros and cons, but any of the three allow a community to divert immense volumes of waste from landfills, saving space and the planet.

At UrthPact, we truly believe in the power of compostables to save the planet. All of our product lines offer either commercially or home compostable versions. And we continue to move our products towards being 100% home compostable. It’s predicted that the amount of plastic in the oceans will TRIPLE by 2040 without extreme action. By moving certain industries to sustainable and compostable products, we have the opportunity to make a difference and truly save the world.

Industrial Composting: What Is It and How Does It Work?

As 2020 continues on, plastic pollution continues to be a major problem for our planet. And the more that single-use products become a necessity for sanitation and safety, the more important it becomes for us to find an end-of-life solution that benefits our planet rather than harms it. Industrial composting may just be that answer. Industrially compostable bioplastics provide the functionality we need from single-use plastics, but are able to be transported to commercial facilities and turned into usable composts and fertilizers in under 180 days. These facilities are able to process large volumes of municipal compostable waste, allowing communities to not only invest in bioplastics, but to reduce the amount of food waste that is transported to landfills.

Two smaller scale methods of composting are on-site composting and vermicomposting. On-site composting is ideal for small organizations looking to use composting to reduce food waste. These types of compost piles are often made up mainly of food waste and yard trimmings. It requires very little time and equipment, however there is a right and wrong way to do it. Food scraps must be properly sorted and handled, and the compost process can take up to 2 years without manual turning of the pile. Vermicomposting involves adding red worms to a compost bin in order to break down the material into high quality compost called castlings. The worms help to speed up the compost process to about 3-4 months without turning. However, there is the added factor of caring for the worms, and ensuring they have the proper living environment and food sources.

On a municipal scale, there are 3 types of industrial composting: aerated windrow, aerated static, and in-vessel. Each has the ability to process large volumes of compostable waste. In aerated windrow compost, the waste is arranged into rows of long piles (4-8 feet high and 14-16 feet long) called “windrows,” which are turned regularly to provide all of the compostables time in the warm center of the pile where increased heat further encourages breakdown. This method is suitable for a wide range of wastes, including yard trimmings, grease, liquids, and animal byproducts. It can stand up to a variety of climates, and the pile can be adjusted or covered to accommodate weather patterns. The most important factor to consider with aerated windrow composting is that there needs to be a system in place to control odor, due to the open-air nature of the system.

Aerated static composting results in usable compost fairly quickly, between 3-6 months. This method works best with a homogeneous mix of organic waste (like yard trimmings and food waste) but isn’t suitable for grease or animal byproducts. In this method, waste is placed into a large pile that is split up with layers of “bulking agents,” like wood chips or shredded newspaper that allow air to pass through and aerate the pile. Air blowers and other ventilation systems can also be used to aerate the pile. Due to the passive nature of the aeration, these types of piles require constant and vigilant temperature monitoring to ensure ideal compost conditions.

Finally, covered in-vessel composting takes up less space than windrows and can accommodate virtually any type of organic waste. The waste is fed into a covered drum, silo, trench, or similar set-up, which allows for complete control over temperature, air flow, and other variables. The material is mechanically turned for aeration, and compost is created in just a few weeks. Due to this high speed of formation however, the compost then needs time to allow the microbial activity to balance and the pile to cool before it is usable. While this method provides the most control over the compost and a fast turnaround, it is the most expensive of the 3 methods due to the technology requirement.

Not only does composting provide a better end-of-life option for bioplastics and other materials, it can divert a huge volume of waste away from landfills, where that waste can be converted into something new and usable for agricultural and other purposes. Up to 50% of the waste that is currently being landfilled could be composted instead. When food waste breaks down in landfills, it does so anaerobically, meaning that it does so without oxygen present. This process releases methane gas, an extremely harmful greenhouse gas. The compost process brings oxygen into the equation, allowing carbon to be sequestered away in the final compost material rather than released into the atmosphere.

Besides providing usable fertilizers and compost, industrial and commercial compost facilities provide twice the number of jobs currently created by the recycling industry, and triple the jobs created by landfilling. There are also a huge range of environmental benefits provided by composting that cannot be matched by either recycling or landfilling. Composting on the municipal level can help communities to reduce their waste volumes and protect the planet. Commercially compostable products and packaging are the first step towards creating a fully circular economy for single-use products, and saving our planet from the plastic noose that is continually tightening around it.

For more information on bioplastics and the compostable future, CLICK HERE.

Marine Degradable Bioplastics Are The Key To Saving Our Seas From Plastic

53,333 blue whales. 1,333,333 elephants. 615,384 school buses. What do all of these numbers have in common? Take a minute, think about it. What could blue whales, elephants, and school buses possibly have in common? We’ll give you a hint: they’re all really heavy. Give up? Well, that number of blue whales, elephants, and school buses is how many of each of those add up to 8 million metric tons. But what’s the significance of 8 million metric tons? What could possibly weigh that much? That’s the amount of plastic waste that is dumped into oceans every single year. Isn’t that shocking? To put this in perspective, there are only 25,000 blue whales left in the world. That means we dump twice the weight of the world’s living blue whales’ worth of plastic into the oceans each year. It’s mind-boggling!

We all know that marine plastic pollution is a worldwide issue that not only threatens marine wildlife, but humans as well. Any plastic that is consumed by marine animals that humans then consume as seafood has the potential to transfer harmful effects to us. One of the easiest ways to help plug the plastic faucet at its source is to choose products that are made from marine degradable materials. But what does marine degradable mean? Basically, a product that is certified for biodegradation in a marine environment will either list successful passing of ASTM D6691–an American test standard for marine biodegradation–or will show a TUV OK biodegradable MARINE certification. The difficult catch in marine certification is that organizations don’t want to encourage people to toss trash in the ocean just because it will biodegrade. Therefore, the OK MARINE certification can only be reported for products that are meant for marine usage (like fishing gear for example).

When products or materials are marine degradable, this means they will disintegrate (ie, physically break down) into pieces smaller than 2mm in just 3 months, and will be completely biodegraded (ie, chemically broken down to innocuous elements and compounds) in under 6 months. This makes these materials much less likely to harm marine wildlife. From plastic bags, to microplastics, to balloons, to kilograms of congealed plastic waste–any of these have the potential to be fatal to marine life. In fact, in 2006 a Cuvier’s beaked whale was found dead after a single plastic bag entangled its intestines. A whale was taken down by a single plastic bag. We tend to brush off animal deaths that are caused by plastic internally; if we can’t visually look at it and see the damage that plastics have done, then plastics aren’t at fault, and we can continue justifying their usage to provide convenience for ourselves . But these animals deserve an ecosystem where they don’t need to worry about consuming something that clearly resembles food but will eventually kill them.

It’s a tough position to be in. While we want to have the convenience of single-use plastic products, we do so at the expense of our oceans and marine wildlife. At UrthPact, it’s our goal to keep 25 billion pieces of plastic from oceans and landfills. And while this is just a tiny dent in the 51 trillion pieces that are already floating around in our oceans, we want to do everything in our power to make a difference. Every single straw, coffee pod, or piece of cutlery we produce and sell is one less plastic piece headed to a landfill or the ocean. Each little dent we make is a piece of the larger solution. By beginning the transfer over to marine degradable and compostable materials, we truly have solved the single-use plastics problem. Now, we just have to share that solution with the world. Things are changing. What can you do to make a difference?

What Are Bioplastics and Why Do They Matter?

Bioplastic. It’s a word that’s becoming much more common in our vernacular in recent years. The single-use plastics industry is constantly looking for new ways to be more sustainable, and integrating bioplastics into the industry is one of those ways. We started with recycled-content materials, but those materials will still end up in landfills at some point. We then moved on to bio-based materials, which are made completely or mostly out of renewable or biological materials. While a great step forward, bio-based materials aren’t necessarily biodegradable or compostable, and most likely will still end up sitting in landfills. Finally, we’ve reached bioplastics, which by definition are biodegradable, meaning they will break down to innocuous elements or materials. As bioplastics become more common in the single-use consumer products industry, it’s important for businesses to understand exactly what bioplastics are, and why they’re important.

The written definition of bioplastic is a type of biodegradable plastic derived from biological substances rather than petroleum. The key word here is biodegradable. Other materials that are labeled as bio-based or other phrases are not guaranteed to be biodegradable; they only indicate that a large portion of the materials used to make the product are biologically-based. It states nothing of the product’s end-of-life. Many bioplastics also qualify as compostable, meaning that the elements or compounds they break down into also contribute to and create a great nutrient-rich fertilizer with no ecotoxic effects and supports plant growth. This is a key difference between bioplastic products and bio-based products. This difference makes bioplastics the more planet-healthy option.

There are two bioplastics that currently dominate the industry: polylactic acids (PLAs) and polyhydroxyalkanoates (PHAs). The main differentiators between these two materials are their feedstocks and their compostabilities. PLAs are made from a corn starch or sugar cane base while PHAs are from a canola oil base. On the back end, PLAs must be composted in industrial or commercial facilities under specialized conditions, while PHAs can compost just about anywhere on Earth (including being able to biodegrade in both the oceans and landfills in many cases). The complexity of the compost conditions for PLAs is one of the largest limiting factors for the material, as it can be difficult to find facilities that will be able to compost them. PLAs also become brittle over long periods of time, giving them a shorter shelf life than products made from other materials. For PHAs, the novelty of the material is it’s greatest barrier. There is still much research to be done to scale up the industrial production of PHAs cost effectively.

Humans like convenience. We like not having to worry about our drink spilling from a sippy lid because we didn’t want a straw. Bioplastics allow us to have the convenience of a straw and lid without any of the environmental guilt associated with petroleum-based plastic products. As usage of single-use products and packaging continues to rise, we need to find ways to lessen the impact of these products on the planet. Making them from bioplastics is a start. Especially PHAs, which will break down nearly anywhere on Earth in a fairly short period of time. The single-use problem has truly been solved. The question is, are we ready and able to make the changes that we need to? Or will we let our planet and the wildlife that calls it home continue to suffer? It’s time for a change. It’s time to do the right thing. It’s time for the bioplastic future.

The Summer Of Sustainability – How Plastic Pollution Effects Wildlife

A sea turtle with a straw in its nose. Whales washing ashore with stomachs filled with plastic bags. Birds feeding plastic pieces to their chicks. Wildlife all over the planet suffers at the hands of plastic pollution, whether they are terrestrial or marine. We tend to only consider marine species when looking at the plastic pollution problem, but it affects terrestrial species just as much. This past week we celebrated World Lion Day, World Elephant Day, and World Hirola Day. Each of these species has been affected by plastic pollution. Elephants in particular have suffered, as landfill waste has overflowed into their habitat, and many animals have suffered from consuming plastic waste.

Besides elephants, a huge range of wildlife are negatively affected by plastic pollution. Some of the most common are marine mammals, seabirds, sea turtles, and camels. It’s estimated that 54% of all marine mammals have been impacted by plastic pollution in some way, whether it’s ingestion or entanglement. ⅔ of all seabirds worldwide are negatively affected as well. All 7 species of sea turtles have problems with plastic, especially plastic bags which can mimic jellies in the marine environment. Jellies are a key food source for sea turtles, and therefore it’s estimated that over 50% of all sea turtles have ingested plastic debris at some point. Camels are also impacted mainly by plastic bag waste, and they account for half of the camel deaths on the Arabian Peninsula each year.

Plastic waste negatively impacts wildlife in a variety of ways. One of the main ones is due to the fact that animals consume and ingest plastic waste thinking it’s food. This can lead to a variety of problems. Animals cannot digest or pass plastic once it’s in their digestive system. Therefore, it clogs up their digestive tract, giving the feeling of being full (since there’s no room in their stomachs) but without any of the essential nutrients they need. They basically starve to death with a stomach full of plastic. Ingested plastic debris can also cause internal injury and tear the delicate soft tissues of the digestive tract. AND plastic debris tends to pick up chemical pollutants in the environment before they are ingested, which are then leached into the animal’s system as the body attempts to break it down. Entanglement is also a dangerous consequence of plastic pollution. Not only can it cause external injuries that can become infected, it can drown air-reliant marine life due to immobilization from entanglement. The same can be true for entanglement on land; animals can be rendered immobile, and can die of starvation or dehydration.

Plastic affects more than just humans. For hundreds of thousands of years after it is produced, it affects an enormous range of ecosystems and wildlife. From toxic chemical effects on microorganisms to entangling the internal digestive system of something as large as a sperm whale, plastic affects all walks of life. And it’s our job as humans to protect the other species that call our planet home. We created this plastic problem, and therefore it’s our job to solve it. Beach cleanups and pulling plastic waste from open water are great starts. But it’s time to plug the problem at the source. We need everyone working together to solve the plastic pollution problem. What can you do?

Compost 101: The What, The How, and The Why

What is compost? We’ve been hearing that word a lot recently in the bioplastic industry, as compostable materials have been surging in popularity in recent years. Compost is defined as “a mixture that consists mainly of decayed organic matter and is used for fertilizing and conditioning land.” More simply put, compost is decayed organic matter: basically broken down food scraps, lawn cuttings, and other nature- or plant-based materials that have been discarded and decomposed by both the elements and microorganisms. Compost is used to fertilize soil, and add nutrients that support plant growth and help microbial communities flourish. It’s a great alternative to chemical-based fertilizers. The composting process opens the door for us to be able to create products with a completely circular lifecycle.

There are two main types of compost: industrial (aka commercial) compost, and home (aka backyard) compost. The two types of compost are distinguished by the conditions under which they occur. Industrial compost occurs at much higher temperatures than can occur in nature and requires a specialized community of microorganisms in order to break down the materials added to the pile. Normally, industrial composting is done in a special facility where these conditions can be met. Home compost can occur in any backyard compost pile, or in a variety of other natural environments. It occurs at ambient temperatures and with natural communities of microbes. Materials that are home compostable have a truly circular lifecycle, as they contribute back to the Earth they came from.

Of all of the waste that humans produce that is transported to landfills, over 50% of it is made up of materials that could be composted. This means we could reduce the volume of waste in landfills worldwide by 50 PERCENT! This would not only reduce the size of landfills worldwide but also reduce the amount of greenhouse gases released into the atmosphere. In landfills, compostable materials will biodegrade anaerobically (without oxygen) and release methane gas, a very common greenhouse gas that contributes to global warming. In a compost setting, materials biodegrade aerobically (with oxygen), and sequester away carbon in the nutrient-rich compost that is created through the composting process, instead of releasing the harmful methane gas. Compost also has a variety of other benefits, not only for the soil and the soil ecosystem but for a variety of other industries as well.

We have often seen recycling as the solution to our waste problem. But recycling is inefficient and not a completely circular process. Recycling is more akin to downcycling, as products made from recycled materials are often of a much lower quality than the originals. As waste continues to pile up, we need a better solution to the plastic pollution crisis. Compostable materials are exactly that. Many home compostable bioplastic materials will not only break down completely in home compost but also in landfill and marine ecosystems as well. By encouraging communities to implement composting programs, the community will not only save money but the planet as well.

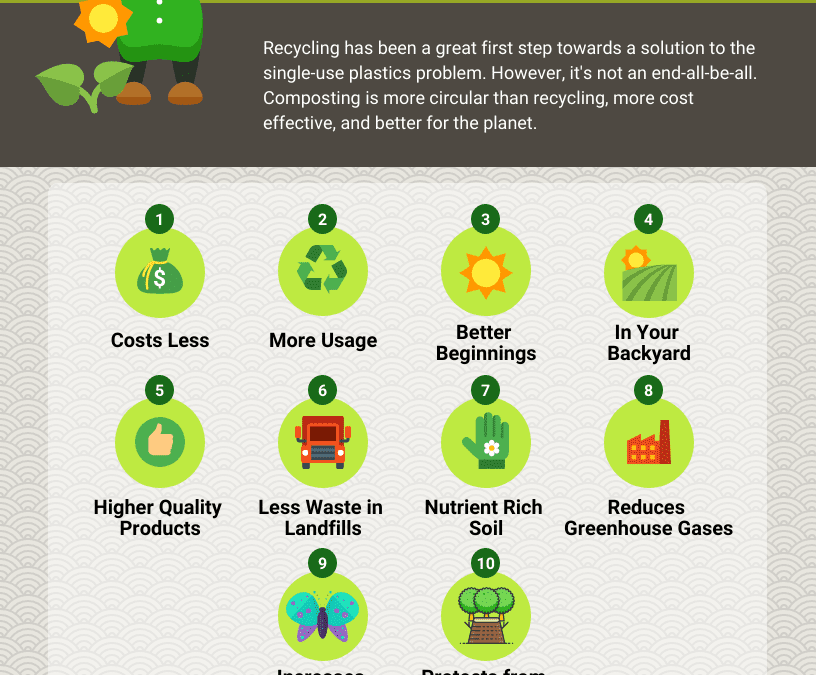

10 Reasons Why Composting Is Better Than Recycling

Up until recently, recycling has been a great method of addressing plastic pollution in our society. It allows us to get a few more uses out of a product or material rather than simply just throwing it away. But realistically, material can only be recycled once or twice before it is of too low a quality to be recycled again. And, products made from recycled materials are usually of a lower quality than were the original products. Compostable bioplastics provide the opportunity for products to be remade indefinitely, creating a fully circular economy for packaging and other products. Here are 10 reasons why compost is better than recycling:

- Composting costs less . Collection and disposal costs for recycling are 7 TIMES HIGHER than those for composting (about $166 per ton for recycling vs. about $23 per ton for composting). Plus, compost done at home is absolutely free!

- Allows for more usage out of a material. Materials can normally only pass through the recycling system one to two times. This is due to the fact that the recycling process reduces the quality of traditional plastic materials every time they pass through the system, which essentially makes recycling actually downcycling. Composting on the other hand creates a nutrient-rich fertilizer that can then be used to grow a feedstock to create brand new material.

- Better beginnings. Compostable materials come from natural sources, like corn starch, sugar cane, and canola oil. Their production processes are carbon neutral, meaning they don’t have negative effects on our planet. The production of traditional plastic materials on the other hand releases a variety of toxic and unhealthy chemicals into the atmosphere.

- Can be done in your backyard. The entire compost process can be done for free in your home! This is not only cost-saving but will provide healthy soil for a home garden.

- Higher quality products. Because recycling produces lower-quality materials, the products made from those materials are also of lower quality. But compostables are always fresh materials, meaning a higher quality product for the customer.

- Decreases the volume of waste in landfills. Over 50% of the waste taken to landfills can actually be composted, the bulk of which is food waste. If we removed this waste and composted it, we could greatly decrease the amount of land space that is currently occupied by landfills.

- Creates nutrient-rich soils. Compost is made of decaying organic matter, which provides a wide variety of nutrients to the soil. These nutrients can then help to support plant growth and strong microbial communities.

- Reduces greenhouse gas emissions. When compostables break down in landfills they release methane gas, which is one of the most common greenhouse gases in the atmosphere contributing to global warming. However, if those compostables are properly composted, then the carbon that makes up the methane gas is sequestered away in the soil, rather than released into the atmosphere.

- Increases biodiversity. Compost in the soil helps to attract a variety of microorganisms to assist in the composting process, as well as contribute to the microbial and insect biodiversity in the soil. Increased biodiversity indicates an overall healthier ecosystem.

- Compost protects from soil erosion. Having a healthy layer of compost helps to prevent valuable and fertile topsoil from being eroded away by wind or rain. This retains the fertility of the soil for future seasons.

While compost may seem like a new process to us, it’s not. Composting is a completely natural process that has been occurring on Earth since the first plants appeared. We have the ability to take advantage of this process so that we can not only have the convenience of single-use products but protect our planet as well. It provides such a wide range of opportunities that we currently aren’t making use of. Recycling was a great step in recognizing we needed to do something to alleviate the plastic pollution problem, but now we need to continue to build on the knowledge that we’ve obtained. We need to take action to continue protecting the planet, especially now. Compostables and composting are key opportunities to achieve this goal, and we need to continue developing and understanding these processes to protect our planet.

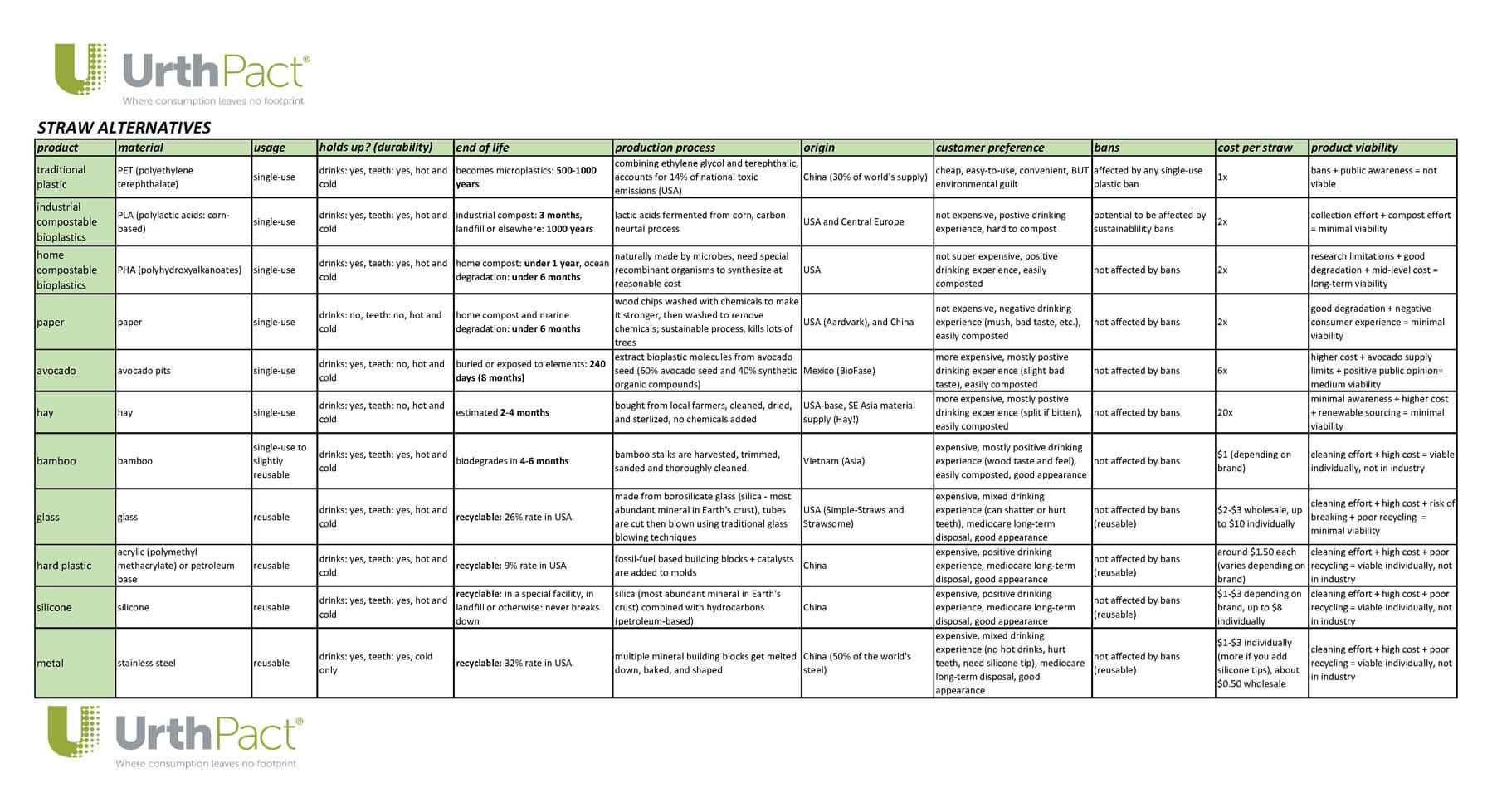

The Great Straw Predicament – How Can You Satisfy Both Customers and the Planet?

Plastic drinking straws have been one of the top targets of the single-use plastics movement because of their easily disposable nature and a viral video of a sea turtle having a straw removed from its nose. Straws are something that can easily be replaced with more sustainable alternatives, whether those alternatives be reusable or single-usage. But what’s the BEST choice? How can you check all the boxes with a straw alternative: planet-approved, customer satisfaction, and ensured contaminant-free? Industries have many different choices for single-use straw alternatives, and different industries will have different organizational and customer needs to satisfy. And individual users will have different straw usage needs than larger industries.

When it comes to individual and personal usage, reusable straws may be the best option. Proper cleaning and safety are the most important considerations with the reusable options, but when being used in an individual setting, these can be easily accounted for. However, restaurants use hundreds of straws daily, so it’s not feasible to properly scrub hundreds of reusable straws. This requires a single-use option that not only takes the planet into account, but the cost of the product and the customer as well. Many single-use alternatives fall flat on customer expectations and experience, making it difficult to satisfy your customers that require or request a straw.

Paper straws are one of the biggest offenders of customer DISsatisfaction. While they are reasonably priced and (assumingly) harmless to the planet, most people are not going to have an enjoyable drinking experience. Especially when that paper straw is combined with a plastic to-go lid that only emphasizes the structural problems of the straw. Liquid quickly turns the straw to mush (even the best on the market will only last about an hour or 2), which leads to a bad taste in your mouth, and more likely, the need for a second straw to finish your drink. It’s also important to point out that paper straws aren’t necessarily as environmentally friendly as we all think. Because paper is an “inherently compostable” material, paper straws are not required to be certified by any governing body like BPI or TUV before claiming they are compostable or ocean-safe. While 100% paper is compostable, paper straws are NOT 100% paper — they include glues, inks, and most importantly, coatings to make them somewhat liquid-proof. Meanwhile, home compostable bioplastics sport certifications from a variety of sources stating their qualifications as compostable and marine-degradable, including TUV’s OK compost HOME and INDUSTRIAL certifications, a BPI certification, and successful ASTM D6691 test results.

Paper straws were a good first step. Industrial compostable PLA straws were also a good first step. The single-use industry has been working tirelessly to find a material that satisfies everyone’s needs: the buyer, the user, and the planet. Home compostable bioplastic straws like those made from PHA provide that solution. They meet the price point, perform as the customer expects and give a positive drinking experience, and will break down anywhere on Earth in under a year. The material and technology are groundbreaking, and the home compostable revolution is here to stay. As the Summer of Sustainability continues, it’s on all of us to encourage our local businesses to make better choices for our planet. The solution has arrived; let’s put it to use.